A legacy

of innovation

By 1946, the war had finally been won, and America was looking to the future. It was a time of hope and opportunity – and if there was one person who saw the potential of the times, it was American industrialist Henry J. Kaiser.

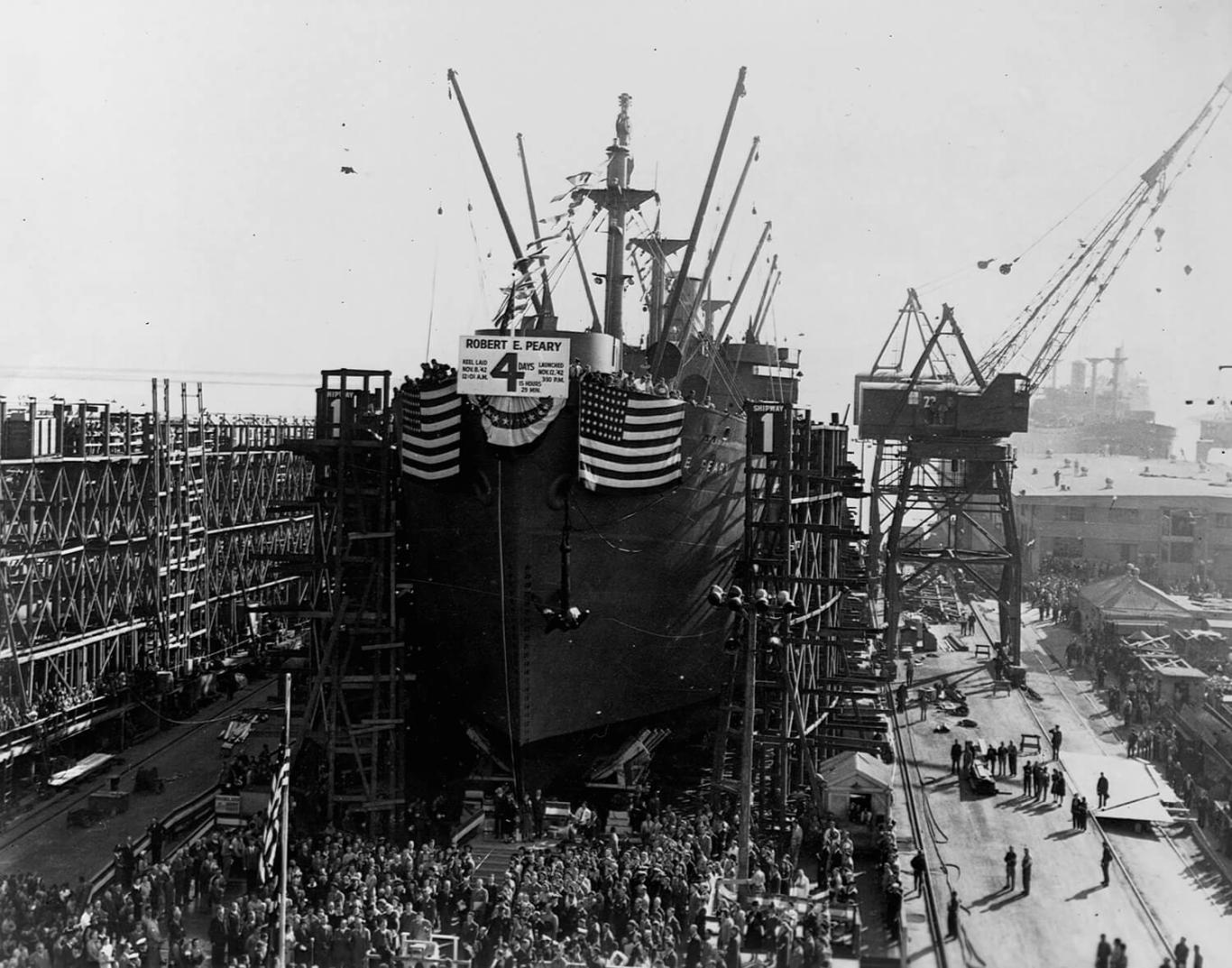

Henry J. Kaiser was an inspired entrepreneur. During World War II, Henry J. Kaiser’s shipyards built almost 1,500 ships for the war effort and forged a reputation for speed, efficiency, and workplace equality. But, as the war wound down, Henry J. Kaiser could imagine a future of growth and opportunity and he wanted to help create it. That vision led to the lease (and eventual purchase) of three aluminum facilities from the U.S. Government.

Since then, Kaiser Aluminum’s reach has expanded with locations across North America, partnering with customers around the world. Aluminum produced by Kaiser can be found in everyday applications, from the cars we drive and airplanes we fly, to the cans that hold our favorite beverages.

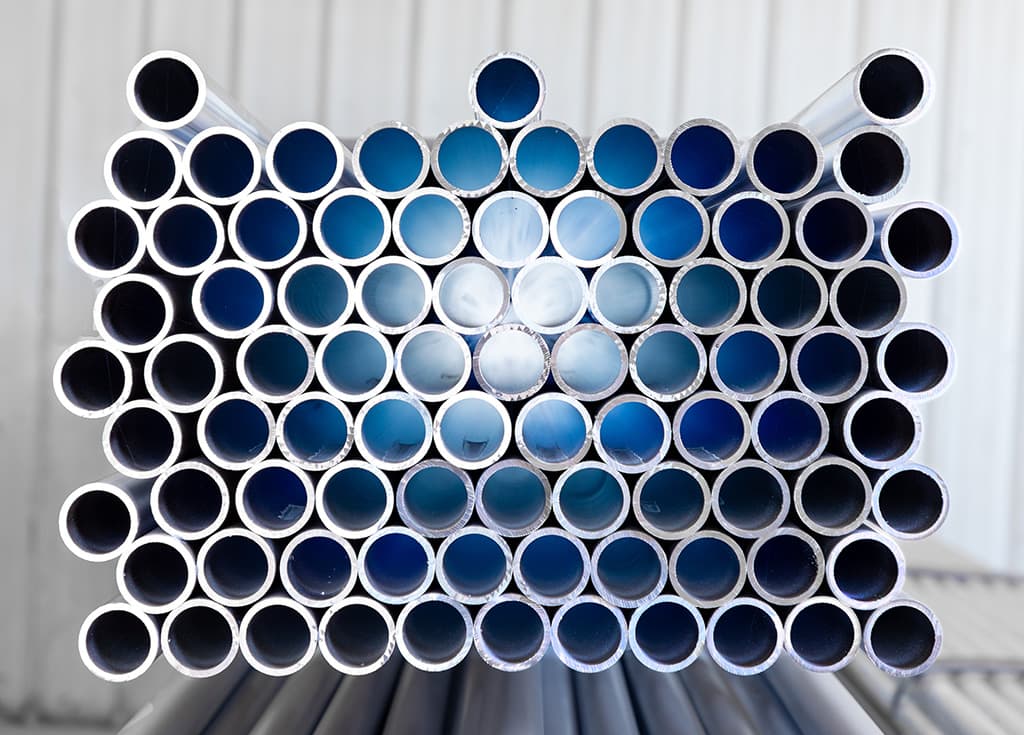

We focus on metallurgy, process technology, and highly engineered innovative solutions in all our chosen end markets. Today, Kaiser Aluminum continues to offer premiere semi-fabricated aluminum products for major suppliers and manufacturers around the world, in the aerospace and high strength, packaging, general engineering, and automotive end markets. We remain dedicated to continuing Henry J. Kaiser’s legacy of top-tier aluminum product manufacturing in North America, both now and in the future.

The rest, as they say, is history.

(Check out the highlights below in our timeline)

Great American industrialist, visionary, and business leader

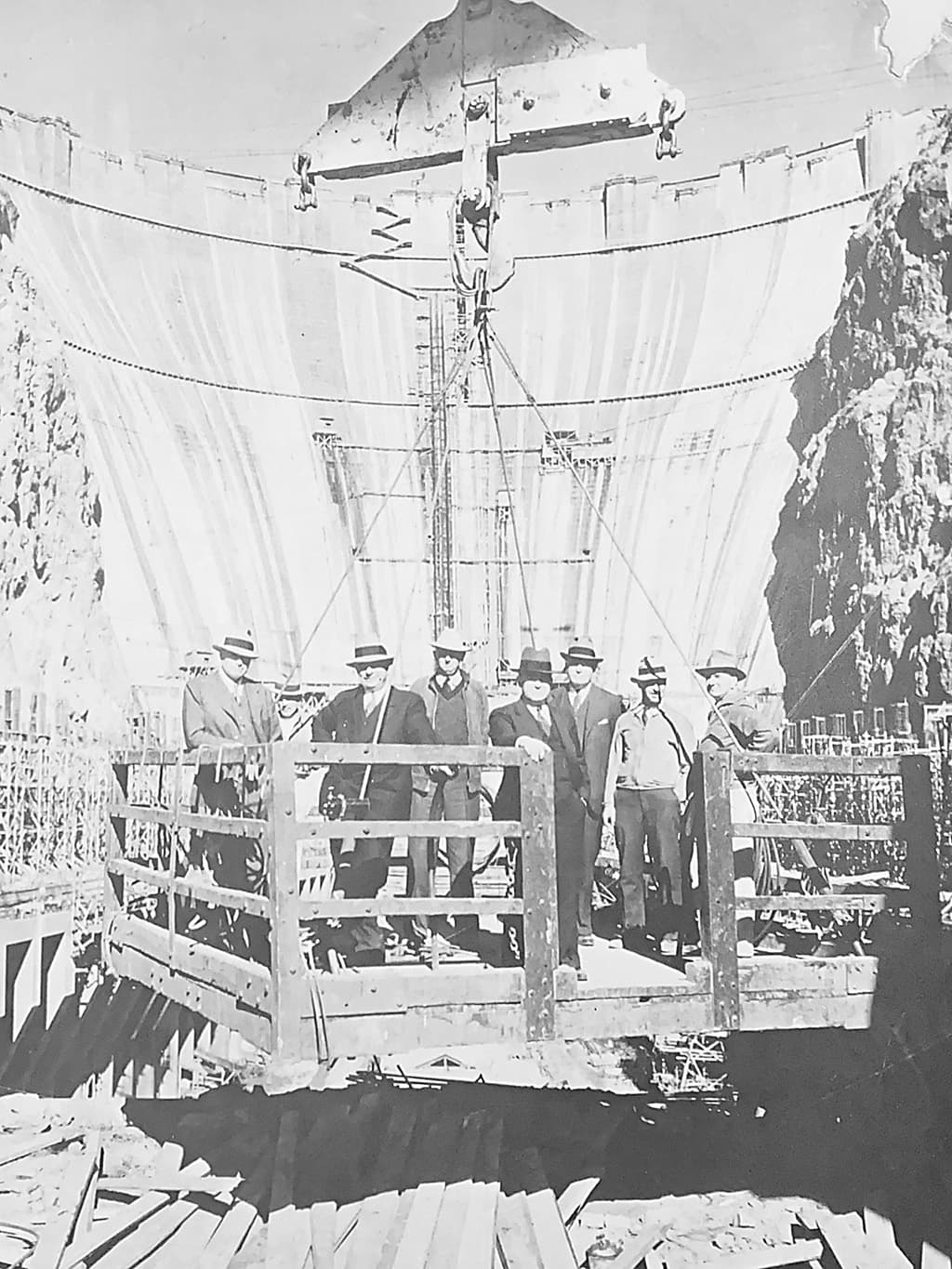

Henry J. Kaiser and the Six Companies begin construction on the Boulder Dam (later renamed the Hoover Dam) on the Colorado River in Nevada to provide water and hydroelectric power for the developing Southwest region. The dam is a National Historic Landmark and, to this day, considered a feat of engineering.

The Henry J. Kaiser Company is part of the consortium that builds the Grand Coulee Dam on the Columbia River in Washington State and the Bonneville Dam on the Columbia River in Oregon. Today, the Grand Coulee Dam is the largest hydropower producer in the United States and supplies power to Kaiser Aluminum’s Trentwood facility in Spokane Valley.

Kaiser Aluminum’s history grew out of Henry J. Kaiser’s involvement in the war effort. Kaiser’s shipbuilding company built almost 1,500 Liberty ships and their successor, Victory ships – fast. In fact, Kaiser became a household name for pioneering innovative and efficient shipbuilding methods.

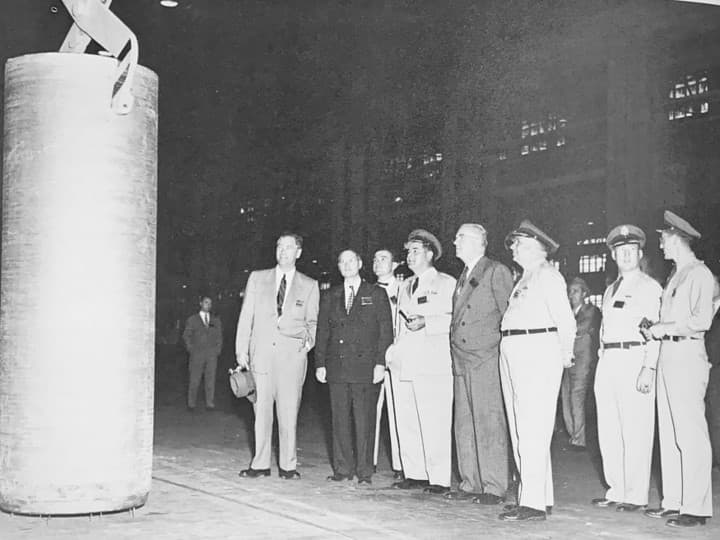

Inspired by wartime uses of aluminum and a bold vision for the future, Henry J. Kaiser enters the aluminum business with the founding of Permanente Metals, which is later renamed Kaiser Aluminum, with the lease and eventual purchase of facilities in Mead and Trentwood Washington.

Henry J. Kaiser and business partner Joe Frazer found the Kaiser-Frazer Corporation to produce cars for the post-war boom, and the first of the company’s 750,000 cars hit the road. Amid steel shortages, Henry J. Kaiser proposes the visionary idea to “build the cars with aluminum instead of steel.” The idea was ahead of its time and did not advance beyond the experimental stage. Today, Kaiser Aluminum is a major supplier of aluminum extrusions for the automotive industry.

To meet the U.S. government’s need for aluminum during the Korean War, Kaiser Aluminum scales up production by 90%.

By 1953, primary aluminum produced by Kaiser accounts for more than 25% of total U.S. production.

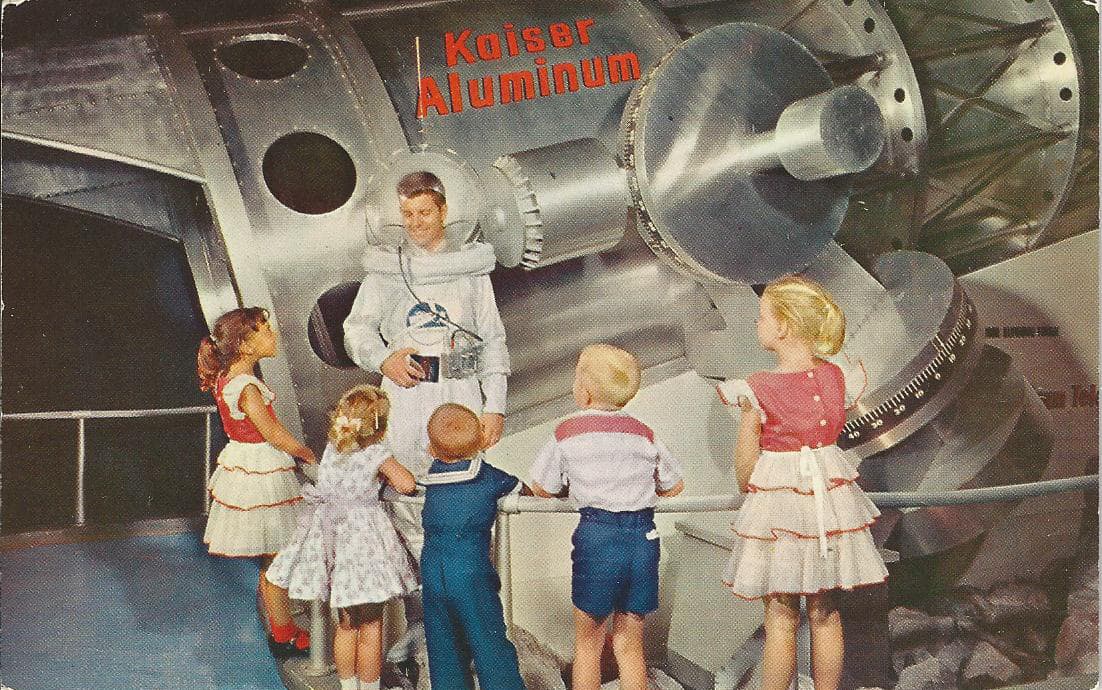

Disneyland opens in Anaheim, California, featuring the Kaiser Aluminum Hall of Fame in Tomorrowland as a pioneering attraction.

Henry J. Kaiser aims to popularize Kaiser household foil on television by launching The Kaiser Aluminum Hour with Paul Newman, and later sponsoring Maverick with James Garner.

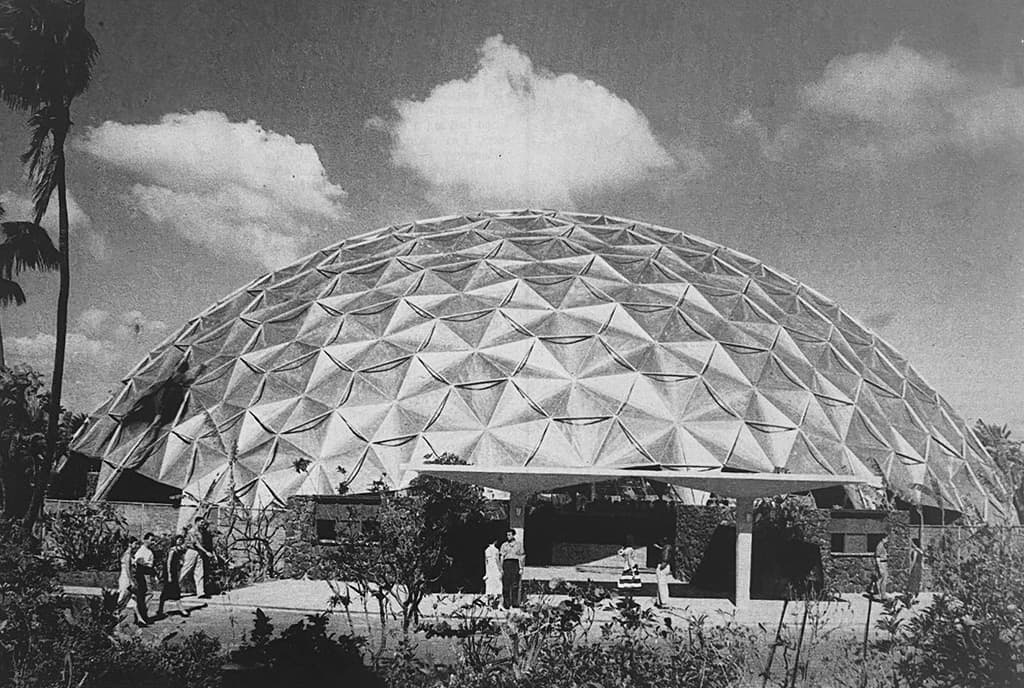

The iconic Kaiser Aluminum Dome is erected in 20 hours at Henry J. Kaiser’s Hawaiian Village hotel in Honolulu, serving as a 2,000-seat resort auditorium for decades.

Kaiser Aluminum products are used in various applications requiring lightweight, durable aluminum, such as boats, railroad cars, and the McDonnell Phantom II aircraft.

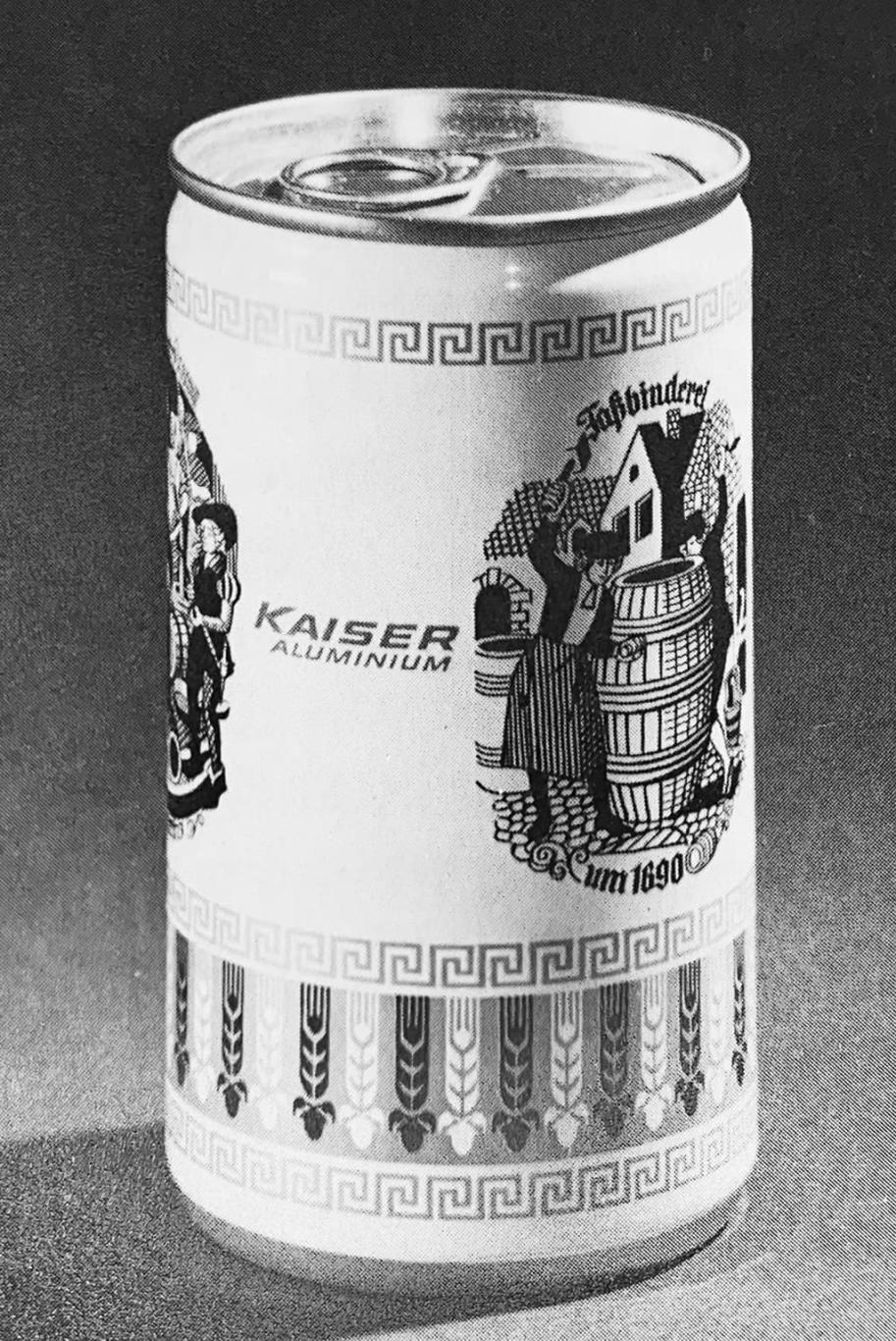

Partnering with Burger Brewing to create the first aluminum-ended beer can, Kaiser Aluminum pioneers coated coil for beverage can production.

By 1968, Kaiser Aluminum is ranked fourth globally in terms of production volume.

Kaiser Aluminum expands its Can-DO program (“Can Disposal Operation”) nationally, and boosts capacity to meet demand for recyclable aluminum cans. As part of Kaiser Aluminum’s commitment to the environment, the company collects more than 15 million pounds of aluminum from consumers, paying $2.25 million for their recycled aluminum.

Amidst the worst U.S. recession since the Great Depression, Kaiser Aluminum perseveres through challenging business conditions and continues to supply aluminum to the automotive and construction end markets, two industries hit hardest by the recession.

Kaiser Aluminum restructures, exiting can sheet and other operations and filing Chapter 11 in 2002. The company repositions to concentrate on the manufacture of value-added, semi-fabricated aluminum products, maintaining its customer base with timely delivery, quality, and ethical corporate culture.

Kaiser Aluminum introduces the KaiserSelect® product portfolio, offering superior consistency, performance, and cost-efficiency for customers.

Kaiser Aluminum begins exiting primary aluminum operations.

Kaiser Aluminum ships over 4 million pounds of aluminum plate for military vehicle armor.

One of only three companies worldwide capable of producing plates up to 8 inches thick, Kaiser Aluminum pioneers thicker aerospace plate production and invests $75 million to expand thick plate capacity at its Trentwood facility.

Kaiser Aluminum emerges from Chapter 11 as an independent public company.

The Company allocates $91 million to enhance rod, bar, and tube capabilities.

Kaiser Aluminum embarks on a Digital Evolution within its manufacturing processes, using Intelligent Factory innovation and technologies resulting in significant advancements in efficiency, on-time delivery, and agility.

By the end of 2018, Kaiser Aluminum achieves record shipments and record sales.

Kaiser Aluminum re-enters the aluminum packaging industry by acquiring leading can stock producer Alcoa Warrick LLC in Newburgh, Indiana.

Kaiser Aluminum relocates its headquarters to Franklin, Tennessee.

Continuing with product and process innovation combined with technological advancements, Kaiser Aluminum introduces the KaiserSelect® Next Gen product portfolio.

The Company achieves annual revenue surpassing $3 billion.